ASTM 519-89/ASME SA519 Gr.1010,1015,1020,4140,5120

Seamless Carbon steel Mechanical tube

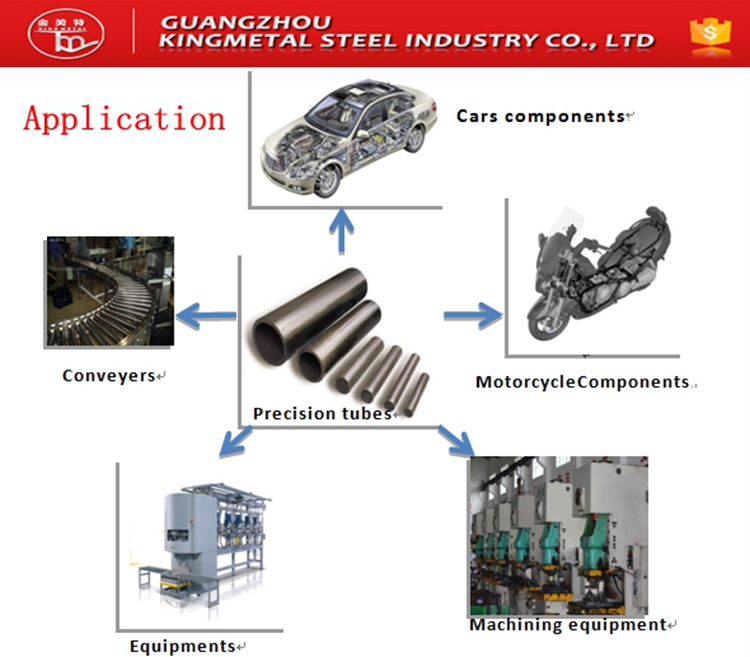

Application

Machinery, Automobiles, Bicycles,Furniture, Appliances and Other machine parts.

Size Range

O.D 12.7-322.8mm

W.T 1.2-40mm

Length: 3-12M or according to your requirements

|

Standard |

Grade |

Chemical Composition% |

||||||||

|

C |

Mn |

P |

S |

Si |

||||||

|

ASTM 519 |

1010 |

≤0.12 |

≤0.60 |

≤0.04 |

≤0.04 |

≤0.35 |

||||

|

1015 |

≤0.20 |

≤0.60 |

≤0.04 |

≤0.04 |

≤0.35 |

|||||

|

1020 |

≤0.25 |

0.3~0.9 |

≤0.04 |

≤0.04 |

≤0.35 |

|||||

|

4140 |

0.38~0.43 |

0.60~085 |

≤0.03 |

≤0.03 |

0.15~0.35 |

|||||

|

5120 |

0.18~0.23 |

0.60~085 |

≤0.03 |

≤0.03 |

0.15~0.35 |

|||||

|

Standard |

Grade |

Mechanical Properties |

|

|||||||

|

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(%) |

|

|||||||

|

ASTM 519 |

1010 |

≥290 |

- |

≥35 |

|

|||||

|

1015 |

≥340 |

≥175 |

≥35 |

|

||||||

|

1020 |

≥370 |

≥215 |

≥30 |

|

||||||

|

4140 |

≥383 |

≥544 |

≥44 |

|

||||||

|

5120 |

≥455 |

≥365 |

≥32 |

|

||||||

Delivery Condition

|

Designation |

Symbol |

Description |

|

Cold finished (hard) |

BK |

Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation. |

|

Cold finished (soft) |

BKW |

The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

|

Cold finished and stress-relieved |

BKS |

Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

|

Annealed |

GBK |

The last cold forming process is followed by annealing in a controlled atmosphere. |

|

Normalized |

NBK |

The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Chemical Composition,Mechanical Properties,Visual appearance and dimensions Test,NDT,Grain Size Test.

Oil-dip,varnish,Shot Blasting